What Really Matters for Solar Trackers

At first glance, a solar tracker seems perfect for outdoor deployment. After all, it’s powered by the sun — what could go wrong?

Quite a lot, actually.

Many manufacturers highlight solar efficiency as the main selling point, but real outdoor conditions are far more demanding than a sunny lab test. For assets deployed in the field, sunlight is just one piece of the puzzle. Other environmental challenges can quietly undermine a tracker’s performance over weeks or months:

- Heat buildup: Even if a tracker efficiently converts sunlight into power, metal enclosures can trap heat. Electronics can overheat, sensors drift, and batteries degrade faster than expected.

- Rain and moisture: Water ingress is a silent killer. Trackers designed only for indoor or light outdoor exposure may fail when heavy rain or condensation occurs.

- Salt air and corrosive environments: Coastal or industrial areas accelerate corrosion. Connectors, enclosures, and PCB boards all face a higher risk of failure.

- Long idle periods: Not every asset moves daily. Some devices sit idle for months, with no maintenance. Solar charging alone cannot prevent slow battery drain or system degradation during downtime.

A tracker that focuses solely on solar efficiency might survive lab tests, but months later, the difference becomes painfully obvious in the field. Failures don’t just mean downtime; they cost labor, logistics, and trust — the kind that your business cannot afford.

What Makes a Solar Tracker Truly Outdoor-Ready

So, if solar alone doesn’t guarantee reliability, what should you look for?

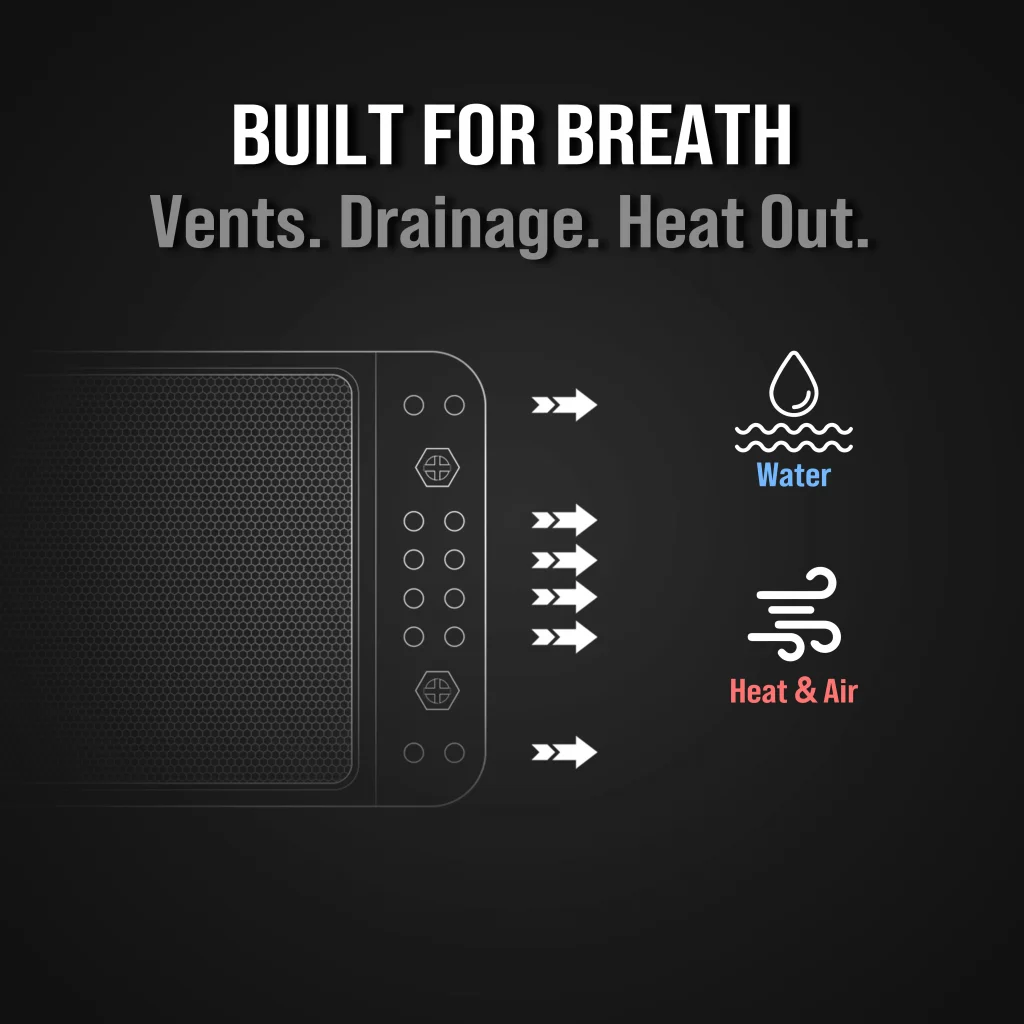

- Thermal management: Good trackers are designed to dissipate heat effectively, ensuring consistent performance even in scorching environments.

- IP-rated waterproofing: Look for devices tested for water ingress (IP65/IP67 or higher) to survive rain, puddles, or high humidity.

- Corrosion resistance: Materials and coatings should withstand salt air, dust, and chemical exposure over long periods.

- Intelligent power management: Trackers need to survive idle periods, manage battery cycles efficiently, and keep data logging uninterrupted.

- Field-proven robustness: Certifications are good, but real-world deployments reveal the true difference. Ask for case studies, long-term tests, or data from existing clients.

Why This Matters for IoT Asset Tracking

For logistics, fleet, or industrial IoT applications, the stakes are high. An asset tracker failure in the field can mean lost cargo, inaccurate fleet data, or gaps in compliance reporting. Choosing a solar tracker is not just about panel size or voltage efficiency — it’s about the entire system’s durability in real-world conditions.

TOPFLYtech’s SolarX series is designed with these principles in mind. Beyond efficient solar charging, every device accounts for heat, water, corrosion, and long idle periods. The result is a tracker that performs reliably in outdoor deployments, whether on containers, trailers, or remote assets.

Bottom Line

Not every solar tracker is truly outdoor-ready. If you only focus on sunlight, you risk failures months later, long after purchase. When evaluating trackers, look for complete outdoor design, field-proven resilience, and intelligent power management. That’s what separates trackers that survive in the lab from trackers that thrive in the real world.